There are a number of factors that can and will alter the amount a stone staircase will cost.

Construction of the staircase

What the staircase is made of

The most expensive stone staircases are cantilever…. How does a cantilever staircase work? A cantilever staircase is one where the solid stone steps (also known as treads) are embedded into a supporting wall on one end, with the other end ‘free’, visible and seemingly floating: the treads are said to be ‘cantilevered’ from the wall.

There are several very good reasons why this form of staircase is so successful and beautiful… and expensive. One of the key reasons is that the structural principle is simple yet clever; and also elegant yet robust and very complex to manufacture and install. Here are some of the key principles:

Each tread supports the tread above it, whilst simultaneously using the tread below for its own support. If you imagine the tread attempting to transmit this load (weight) from the tread above it to that below it without being embedded into a wall, it would simply tilt or ‘twist’ and fall down. It only takes a relatively small amount of twisting restraint from the wall embedment to enable it to carry (i.e. transfer) the load. Each tread has to be clamped by the wall. In reality therefore, each tread is not acting as a pure ‘cantilever’ projecting from the wall, although it is reliant on the wall for its twisting restraint.

Compare this complexity to concrete, where structural engineers can achieve what a cantilever staircase does with the same or improved strength but reduced complexity when considering the ease of casting concrete to such a shape & slope. Next factor in the cost of cladding this concrete with something beautiful …. like stone! You can almost achieve what you get from a cantilever staircase with concrete

Value of Cantilevers

Because of the inherent slenderness and natural beauty of stone, there is generally no need for any other finishes, so the stone itself is the structure and the finished product: Once installed only stone can be seen from any direction you look at the stairs. Cantilever stairs would not be classified as a ‘cheap’ option by any means, and considerable savings can be achieved by building the staircase form out of alternative materials if it is not important to see stone from underneath the staircase.

We specialise in producing stone staircases that are the alternative to cantilever. These are more cost effective but still look as attractive.

Cheaper staircase options

These days with technology it is more common place to have the staircase formed in either concrete or steel. If the house is a new build then the most common route is to form the stairs in concrete as this is the least expensive option. Then with a concrete staircase there are two methods

Shape of Staircase

You have the shape of the stairs and then the shape of each individual step.

The cheapest solution is to have a straight precast staircase where each step tread is the same rectangular size. These treads are cut on a saw and because it is repetitive the cost is kept down. If you plaster the risers this will also keep the price down, however, it does not look as good as a stone riser.

Next is rectangular treads with rectangular risers – each step being the same.

If you require the bottom two steps to be impressive, expanding out on each side with curved extrusions, this will add to the cost of a straight staircase. The cost of this increases as the bottom step normally extends by 300mm on each side and then wraps back around the step, making the tread wider and deeper, and as these steps are normally curved they have to be cut on the waterjet and not a normal saw. Because it is impossible to bend a stone riser around a curved step we make the curved section of the riser out of a solid piece of the stone. We then attach it to the end of the concrete base step, before putting the tread over the top of all other components .

Should you decide to go for a curved staircase this will increase the cost over that of a straight one, as each tread will have to be cut on a water Jet. A waterjet is a technical CAD driven machine for cutting any shape in stone or steel up to 300mm thick using a jet of water 0.4 mm wide. Cutting through the stone with pressure of 87,000 Psi at 6000 bar, the water picks up garnet which helps its cutting ability. This machine, compared to a normal bridge, saw costs far more to run and is slower meaning the cutting component will cost more when done on a water jet.

But, a Curved staircase with extended bottom steps looks fantastic

Size of treads

The size I.e., width of the treads dictates the cost. Stone treads that are up to 1150mm wide are handled by a single operative in both Manufacture and installation. As soon as treads increase above this size every operation in the cutting finishing and installation becomes more costly due to the increased man power required.

The Type of Stone

The type of stone greatly affects the price of a Staircase . At Stoneworld we tend to use three types of stone commonly for Staircases

The most expensive that we often use is Portland Stone Jordans Base Bed. This is the most beautiful and traditional stone, cream in colour with small shells as this is a limestone produced in Dorset, England. We require 14 weeks to get the stone in to produce treads so forward planning is required if this is your desired stone

One popular mid-priced stone for staircases is our Moleanos white Limestone from Portugal. It is very similar to the Portland , slightly denser with a higher shell content generally ¾ the price of Portland

The most cost-effective cream stone that we offer is the white mint sandstone which is produced at 25mm for treads and risers. This stone comes from India and has a high silica content which makes it sparkle. This stone will cost half what Portland stone costs.

On several occasions customers have asked us to produce treads in stone they have selected such as specific marbles or granites. We can do this; however. this will increase the cost.

Thickness of Stone

The thickness of the stone used influences the cost of the staircase. Normally we would produce treads at 30mm and risers at 20mm thick, this would be standard. We can reduce costs by reducing the thickness of treads to 20mm. The cost can also be increased by increasing the thickness of the stone.

Edging Chosen

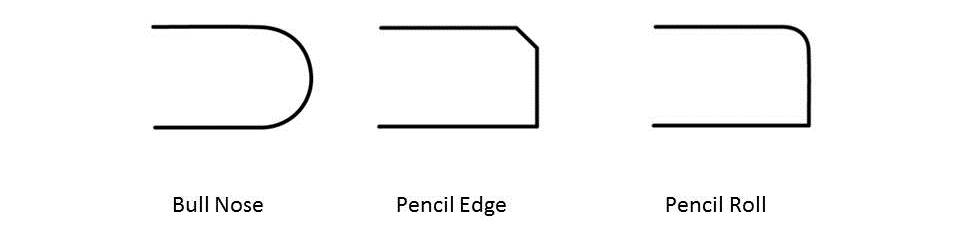

As standard we Bullnose the edge of treads, but we have produced stairs with pencil roll and pencil edge, which can make the stairs look more modern. This will also cheapen the production cost. There are other edges to choose from which will increase the cost as special tooling will have to be purchased to achieve these shapes.

Typical Costs

If we describe a fairly standard staircase of 15 treads and risers with each step being rectangular in shape and each riser 165mm tall rectangular as well. Standard bullnosed finish. Stair size 1100 x 315 x 30mm. Bottom 2 steps extended and curved. Produced in Moleanos

To Build the Concrete Staircase form £9500

To Fabricate and fit stone

Bottom 2 steps £2800

13 Treads and risers £350 each = £4550

Installation £3300

Plus VAT Total £24,180.00

We have not included the cost of the balustrade. We are expecting to team up with a Balustrade company in 2023 to offer the complete service.

This figure is an approximation and only to be used as a guide.

Other issues that can increase the cost of a staircase:

Gallery landing edging

Many customers have a galleried landing whereby the balustrade continues around the landing. It is a nice design touch to continue a 150 – 180mm stone strip around the gallery with front bullnosed edge overhanging the landing and the back square edge going against the chosen flooring, whether it be carpet or stone. Sometimes we put a soft chamfered edge on the back to slope down to mid carpet height.

Lighting strips

Often we are asked to provide slots in treads for lighting strips to be installed by their own electrician. These tend to be LED strips and the slot is normally 20mm wide 10mm deep. Modern technology means these strips should be narrower in the future. Lighting strips are within our capabilities but do add to the cost.

Inlay or carving

Stoneworld has been asked to inlay tread indicators into the front edge of the tread to indicate the edge of the step. This is easily achieved, but time consuming as slots have to be milled, the stone has to be dried and the strips stuck in with expensive glue.

We have also been asked to carve letters on treads before. Design and font, supplied by the customer, can be carved into the tread and if the carving needs highlighting this pattern or letters can be painted with black, gold or white masonry paint.

It is normal that the treads get fitted in position and then the balustrade supplier drills the holes through the stone and concrete staircase to attach the balustrade. On steel staircases we are often asked to cut the holes in the stone. This can be done but is very expensive. It is always advised that the company installing the balustrade drills the holes so they are responsible for locations

Location

Stoneworld is located Near Oxford. Any templating and installation will be more expensive than if the project was in Oxford. Fitting may incur overnight stay allowance and distance traveling and delivery will need to be charged for.

Take a look at some examples of our stone staircase projects by downloading our bespoke staircase brochure here.

Written by:

Rob Parker,

Managing Director