Porcelain is a material that can be challenging to work with. Luckily, no challenge is too ambitious for Stoneworld as we pride ourselves as the innovative stone company.

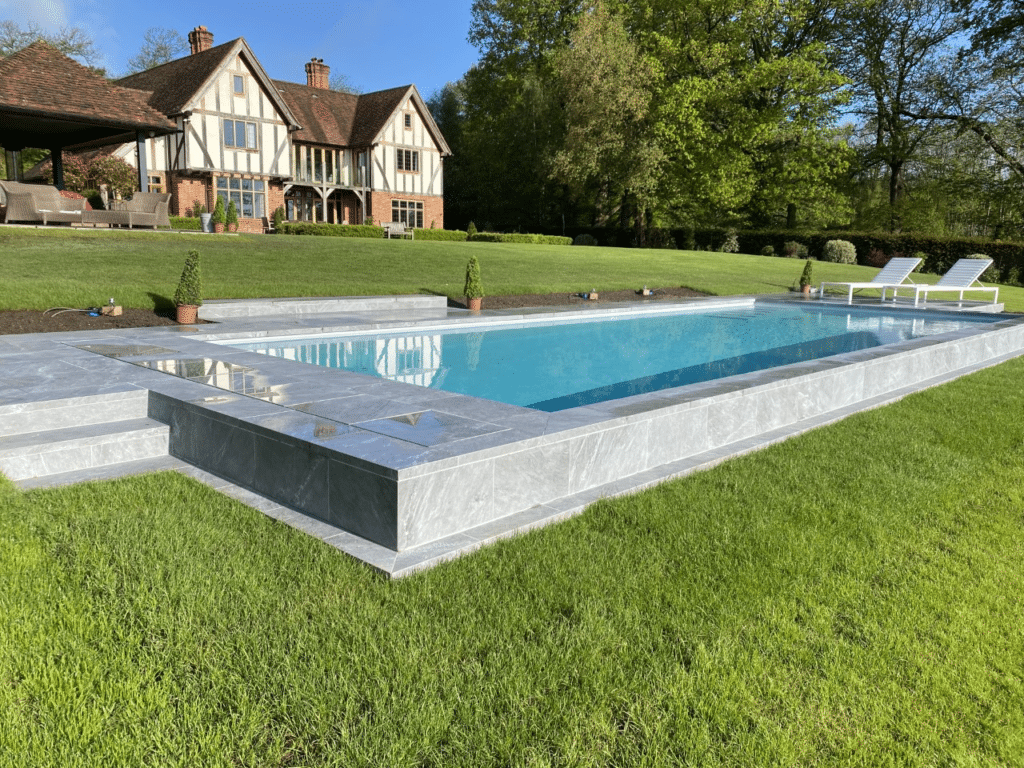

The client’s brief was to create an infinity pool with porcelain copings and paving. The Stoneworld team sat together to discuss different solutions and went onsite to template. The precision cutting was challenging but nothing our highly skilled team could not manage. All masonry cutting happens in our masonry workshop with our waterjet cutter and saws onsite.

For this project, our masonry team precision cut the strips, tiles and a 45° mitre joint. Then we carefully glued, clamped and finished each drop-nose coping. Stoneworld can also provide drop-nose right-angle corners with a mitre join on top and where down stands meet in the corners. Drop-nose copings are available in varying lengths – 600, 900 and 1200.

For advice on any pool building project, do not hesitate to call us on 01844 279274 or email us at sales@stoneworld.co.uk and we will be happy to help.

Stoneworld can solve your installation problems, supply stone, provide porcelain cutting services and offer technical expertise. We stock a broad range of ready to fit porcelain and stone pool copings. Matching paving or flooring is always available. Our team will help you achieve the design and finish you are looking for using stone and porcelain in your projects.