Unlock Creative Possibilities with Stoneworld’s Expert Waterjet Cutting Services

Waterjet cutting is a cutting-edge technology that uses a high-pressure stream of water combined with abrasive materials to slice through a wide array of materials with unparalleled precision. Unlike traditional cutting methods that use heat, waterjet cutting is a cold process. Therefore, it won’t alter the material’s physical properties, warp, or cause damage—an essential feature when working with delicate or heat-sensitive surfaces.

At Stoneworld, we pride ourselves on delivering precision, quality, and innovation through our advanced waterjet cutting services. Whether you’re a designer, architect, contractor, or a creative enthusiast, our waterjet cutting capabilities allow you to transform raw materials into stunning, custom-crafted statement pieces that elevate any project.

Why Waterjet Cutting is Ideal for Stone and Tile

One of the standout benefits of waterjet cutting is its ability to handle natural stone and porcelain tiles without causing cracks or chips. Traditional cutting methods often generate heat or vibrations that can damage these materials. However, the gentle yet precise waterjet process preserves their natural beauty. This makes it perfect for creating detailed patterns, inlays, or custom shapes for countertops, flooring, backsplashes, and decorative features.

This gives you almost limitless creative freedom: We Often Work With These Materials

Natural Stone: Including granite, marble, and other hard stones. These are perfect for custom countertops, flooring, or architectural elements.

Porcelain and Porcelain Tile: Achieve flawless cuts with minimal breakage. Ideal for bespoke tiling or decorative pieces.

Steel and Titanium: Our waterjet cutter can precisely cut even the toughest metals. This opens doors for industrial, artistic, or structural applications.

Non-Toughened Glass: Waterjet cutting allows clean, crack-free cuts for delicate glass projects.

Plastics: Acrylic, polycarbonate, and more — smooth, precise edges every time.

Our state-of-the-art waterjet cutter allows us to cut stone to precise, bespoke sizes, making it perfect for custom pool surrounds and intricate patio layouts. Its accuracy ensures a flawless fit, even for complex or curved designs.

Our waterjet cutting service is designed to bring your ideas to life with unmatched detail and accuracy. Here’s why working with Stoneworld makes the difference:

Highly Precise Cutting: Achieve intricate designs and fine details that traditional cutting tools can’t match.

No Heat Damage: Preserve the natural beauty and strength of your materials thanks to our cold cutting process.

Eco-Conscious Approach: Waterjet cutting uses minimal chemicals and reduces waste, aligning with sustainable practices.

Fast, Reliable Service: With our onsite facility, turnaround times are quick without sacrificing quality.

Custom Design Consultation and Collaboration

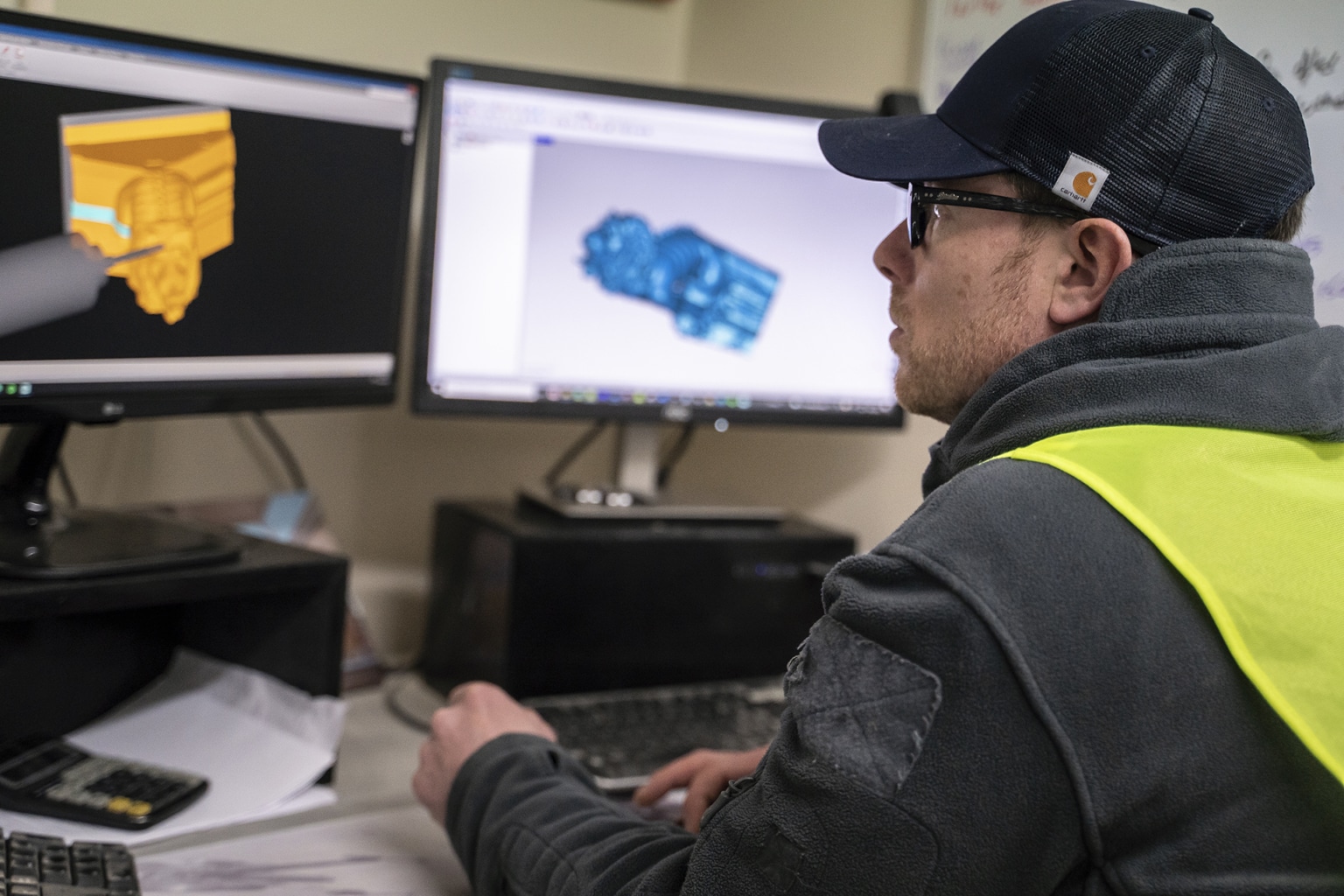

At Stoneworld, we don’t just cut materials—we collaborate closely with you to bring your creative visions to life. Whether you have a rough sketch, a detailed CAD design, or just a concept, our team will work with you to optimize the design for waterjet cutting. We’re happy to offer advice on material choice, cutting feasibility, and finishing options to ensure your project exceeds expectations.

Using CAD (Computer-Aided Design), we can plan and visualise every detail of your stonework before cutting begins. This ensures absolute precision in dimensions and layout, especially for bespoke features like pool copings, steps, and patio patterns.

Commitment to Sustainable Manufacturing Practices

We understand the importance of sustainability in today’s world. Waterjet cutting is inherently eco-friendly compared to other cutting methods. It produces minimal waste and requires no heat or chemical additives. At Stoneworld, we further our commitment to sustainability by carefully managing water recycling and material usage in our workshop.

Bring Your Ideas to Life with Stoneworld’s Waterjet Cutting Service

Ready to explore the possibilities of Waterjet cutting services Stoneworld? Whether it’s a bespoke countertop, artistic installation, or industrial component, Stoneworld’s waterjet cutting service offers the precision, flexibility, and expertise to make it happen. Reach out today and discover how we can help create your next masterpiece.

..At Stoneworld, every project is handled by our experienced craftsmen working in our onsite workshop. This hands-on approach guarantees meticulous attention to detail, quality assurance, and personalized service tailored to your needs. Have a unique design or a challenging cut in mind? Contact us—we’re excited to help turn your vision into reality.