Embodied Carbon: Stone vs Ceramics

Defining Embodied Carbon in stone and other materials

Embodied carbon and carbon footprint in stone and other materials, are a significant consideration in hard landscaping and construction. Where do materials come from, and what impact is its use having on the world we live in? Additionally, with legislation becoming stricter and more environmentally aware, the importance of having the right information to make informed decisions when specifying or purchasing materials is essential.

The embodied carbon of a material is key to understanding the environmental effects of using it. Higher amounts of embodied carbon, mean an increased carbon footprint and ultimately, an adverse environmental impact attached to a project as a result of the processes involved in sourcing.

The first stage of this process is to begin to understand which factors impact the embodied carbon of a product. As a baseline, embodied carbon takes into account all aspects of the processes involved in “creating” it. From cradle to gate, this could, for example, include energy expenditure in forming the material – Mining, sawing, digging etc to remove it from the ground. Then, where a manufacturing or refining process is present, such as porcelain tiling, what factors are present in this process and what is the carbon cost associated with it? There are, as you would imagine, many other factors involved in the calculation, such as transport between sites.

Materials available

There are many materials available for application in construction and hard landscaping, however, as Stoneworld manage primarily porcelain tiles and, above all, natural stone, these two materials are the two most obvious for comparison in this article. They are also among the most common.

Within these product groups, of course, is a wide range of variants, sandstones, limestones, ceramic paving, tiling, etc. As a result, any number which we apply to a product category does not necessarily reflect the qualities of a specific product.

Stone production process

Natural stone is, as the name suggests, a naturally occurring raw material. As such, the first stage of any process involves removing the stone from the ground at the quarrying stage. Stone is removed and cut into blocks, which can then be sawn down into smaller quantities, and shipped in either form. For example, a “Hand cut” sandstone, may be cut on site, or nearby, into slabs and transported in crates. A marble, however, might be transported in its block form to the point of fabrication, where it will be shaped into smaller parts, or a final product. Similarly, a walling stone such as British Purbeck walling stone, will be removed and cut either at the quarry or at the manufacturing site.

The process, evidently, is quite simple and horizontal, with a limited number of very clear points at which carbon is emitted, with transport obviously creating another consideration, such as that of Indian sandstone, which will incur a higher carbon footprint than a similar British sandstone, quarried and manufactured within the UK, such as Stoneworld’s GB Stone range. According to the BSRIA Guide. This can make up around 7% of overall embodied carbon in a material.

Porcelain production process

Unlike natural stone, ceramics/porcelain is a man made product. The creation of porcelain tiles or paving involves a mixture of elements, these principally being a mixture of clays, sands and other materials and agents such as feldspar. The first consideration when looking at carbon footprint is, as with natural stone, the process of sourcing the raw ingredients, and refining them where necessary in order to enter production.

Next, porcelain and ceramic tiles, sheets and other products are shaped and fired in kilns at over 1,000 degrees Celsius. This adds considerable carbon emissions to the product, although it should be mentioned that more modern techniques are often used to reduce this such as recycling heat and use of greener energy in place of the traditional natural gas. As with any material, transport between destinations and to the supplier/manufacturer site is another consideration.

The numbers

In order to make comparisons between the two materials, the BSRIA Inventory of Carbon and Energy offers base numbers, created to assist in calculating embodied carbon. The study takes into account “Cradle to gate” embodied carbon, and does not consider whole life factors such as ongoing maintenance etc. The study also omits carbon footprint caused by transport, so in this instance we will assume the materials are sourced from the same location.

From the available information, we can compare the qualities of “Ceramics”, in this case tiles and cladding. We will also compare the values of “General Stone”, limestone and sandstone.

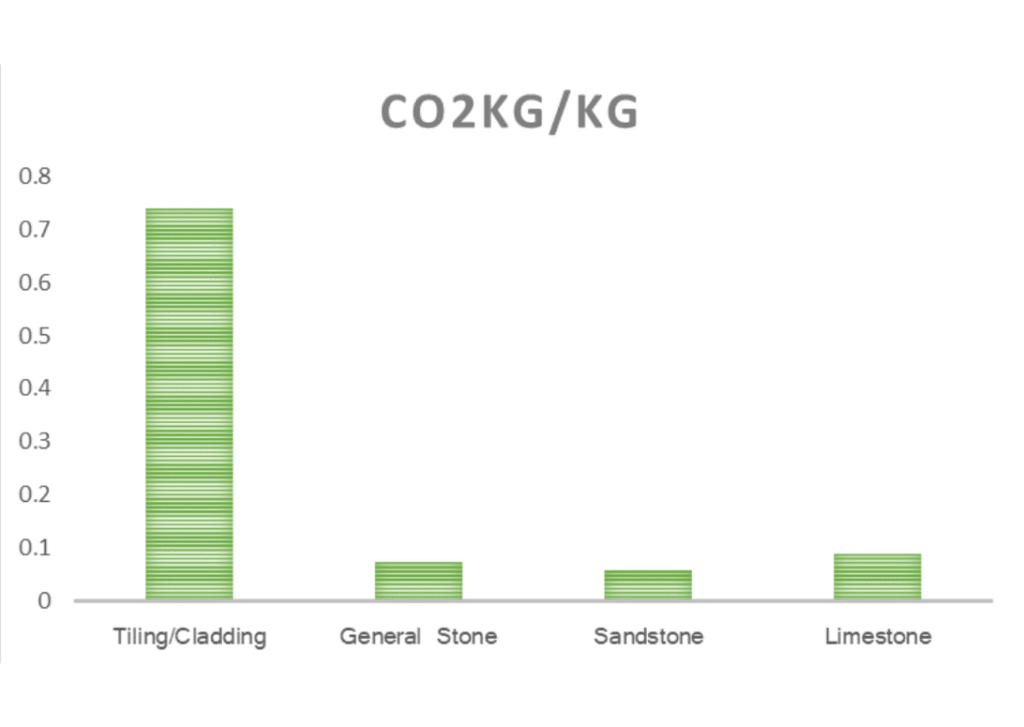

The figures show the following CO2kg/kg of each.

| CO2kg/kg | |

| Tiling/Cladding | 0.74 |

| General Stone | 0.073 |

| Sandstone | 0.058 |

| Limestone | 0.087 |

What we can see, is that the more intensive process involved in the creation of ceramics/porcelain means an embodied carbon % roughly ten times that per kg of stone, with limestone being slightly higher in carbon footprint than sandstone.

The numbers cited are rough examples, and will vary significantly between products, however give some idea of the processes involved in both materials.

Conclusions

When considering embodied carbon, it is always important to check product specific information, such as EPD (Environmental Product Declaration), data sheets and to investigate the origins and processes involved in its production and eventual application. While these numbers cover a general estimate per product sector and are not exact, we can see the impact that material choice can have on the embodied carbon of a building or hard landscaping project. At Stoneworld, we strive to be as transparent as possible about the properties of all of our materials, and work hard to reduce our emissions both on-site and in our supply chain.