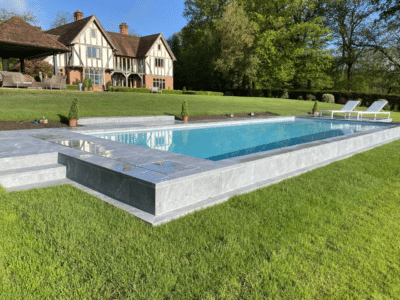

Blue Pool contacted us to assist with these porcelain deck-level pool copings. As an innovation-oriented company, we found a bespoke solution to this porcelain installation challenge.

The challenge

The pool tank construction was completed. However, the installer did not know how to make the deck level coping with the material required. Normally, a customer is guided to choose a suitable stone that a 3-part coping can be made from. It is advisable to choose +50mm thick material at the front and back so these can be rebated strong enough to hold the trough cover and the weight of people. This would normally be 50mm thick, front and back, both produced with a rebate to hold the trough cover which would have slots in or an 8mm joint to allow water through.

In this instance their customer (the end user) chose and purchased a wood effect porcelain tile plank that was only 10mm thick. The pool company was presented with challenging material bought by their customer and asked to finish the pool.

Our Managing Director, Rob Parker, was able to devise a solution that made the project work with the customer’s desired material.

The problems presented in this project were:

- A 10mm tile is not strong enough to span a trough.

- How do we support a thicker trough cover when the tiles are only 10mm thick?

- How do you maintain the 8mm regulation gap when there is no rebate to keep the trough cover in place?

- A porcelain product is perceived to be a very difficult product to cut.

The solution

- Stoneworld cut stainless steel strips equidistance along the trough (like a ‘train track’). Blue Pools had to take out 10mm of concrete.

- Stoneworld joined two tiles together to reinforce the strength. The bottom tile had segmented tabs to sit on stainless steel slots and the top tile was just straight.

- Superior porcelain cutting using the water jet cutter in the masonry workshop, ensures all cut edges on the rebated channel have been finished with a pencil roll. The front edge of the porcelain coping has a half roll bullnosed finish.

The result

Rob’s experience in this field, coupled with the advanced technical abilities available in the Stoneworld masonry workshop produced an excellent working result to overcome the issues identified.

A safe and robust rebated channel looks stylish and neat.

Devising the porcelain cutting solutions was only half the challenge on this project. Blue Pools needed to apply meticulous installation skills to achieve this fantastic result. A successful elegant finish requires attention to detail at every stage. The result: another project to be proud of and a pleased client.

For advice on any pool building project, do not hesitate to call us on 01844 279274 or email us at sales@stoneworld.co.uk and we will be happy to help.

We can solve your installation problems, supply stone, provide porcelain cutting services and offer technical expertise. At Stoneworld, we stock a large range of ready to fit porcelain and stone pool copings. Matching paving or flooring is always available. Our team are here to help you achieve the design and finish you are looking for using stone and porcelain in your projects.

Alternatively, you can complete our enquiry form below and one of our team will be in touch shortly.